Dependable Marine Engineering Services Ltd is a reputable company specializing in marine engineering and maintenance services. With a strong focus on ensuring the safety and efficiency of marine equipment, the company was recently tasked with repairing a winch block for a client in the maritime industry. This case study explores the comprehensive repair project carried out by Dependable Marine Engineering Services Ltd to restore the functionality of a critical winch block.

Client Background:

The client, a leading offshore drilling company, approached Dependable Marine Engineering Services Ltd with a critical issue concerning a faulty winch block. The winch block played a pivotal role in their offshore operations, and its malfunction posed a significant operational risk and downtime.

Challenges Faced:

Dependable Marine Engineering Services Ltd faced several challenges in this project:

- Urgency: The client required a swift resolution to minimize downtime and potential financial losses.

- Comprehensive Inspection: The winch block had been in service for several years, and a thorough inspection was necessary to identify all issues.

- Replacement Parts: Some components of the winch block were outdated and required replacement parts that were not readily available.

Project Phases:

Initial Assessment:

A team of experienced marine engineers conducted a preliminary assessment of the winch block to identify visible damage and wear.

A comprehensive inspection revealed worn bearings, a damaged cable drum, and issues with the control system.

- Planning and Procurement:

Dependable Marine Engineering Services Ltd collaborated with specialized suppliers to source the required replacement parts.

A detailed repair plan was developed, outlining the scope of work, timeline, and resource allocation.

- Repair and Refurbishment:

The damaged components, including bearings and the cable drum, were disassembled and removed from the winch block.

Skilled technicians refurbished and restored these components to their original specifications.

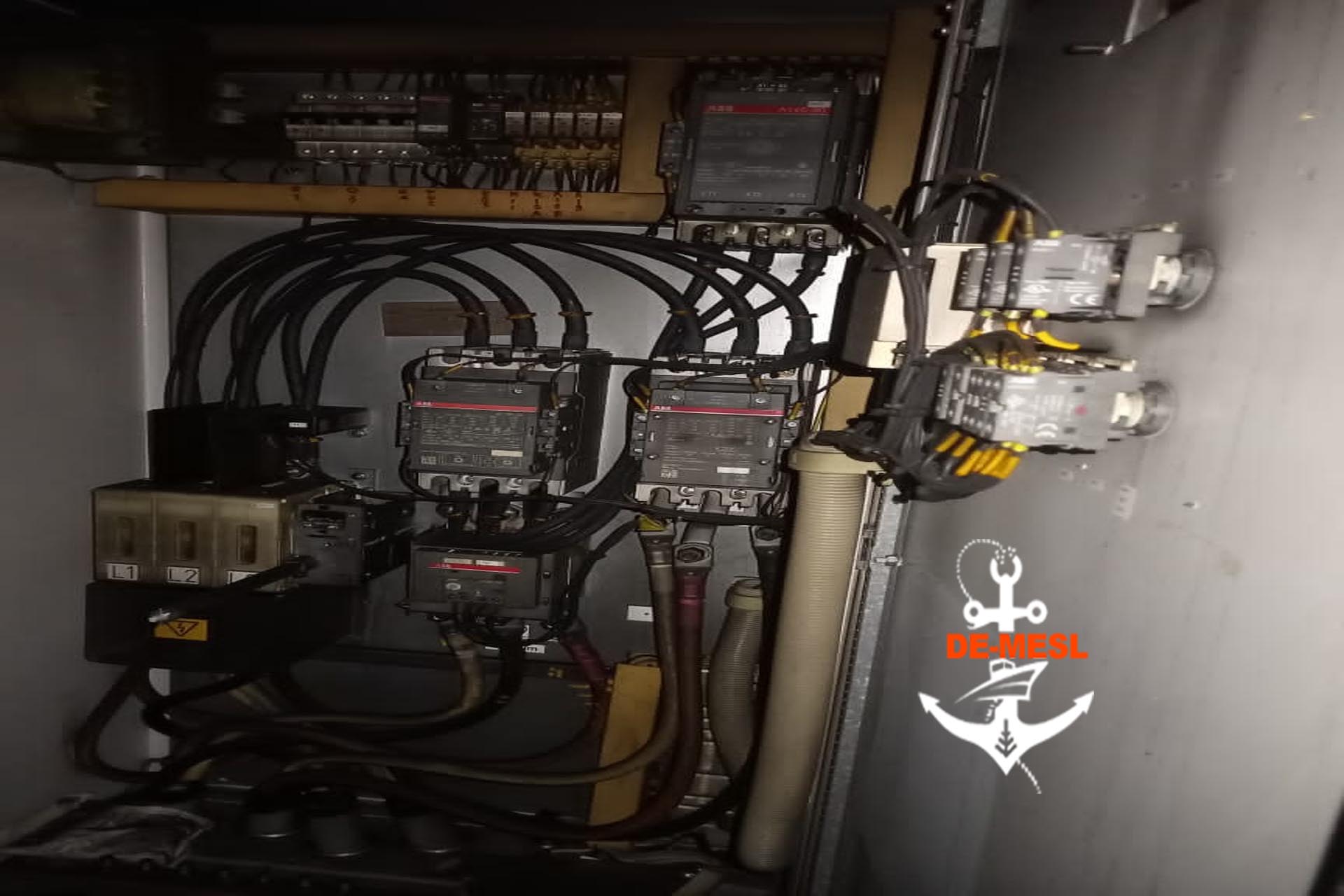

The control system was also thoroughly examined and repaired to ensure precise and safe operation.

- Quality Assurance:

Rigorous quality control and testing procedures were conducted to verify the integrity and functionality of the winch block.

Stringent safety standards were adhered to during all phases of repair.

- Reinstallation and Testing:

The refurbished components were reinstalled in the winch block, and the entire system was meticulously reassembled.

Extensive testing was carried out to ensure the winch block functioned as per the client's specifications, including load testing and operational checks.

Gallery