Dependable Marine Engineering Services LTD successfully executed a complex project involving the removal of a propeller shaft from a marine vessel. The client, a shipping company, faced challenges related to a damaged propeller shaft that required precise fastening and extraction to ensure the vessel's continued operation and safety.

Client's Challenge

The client reported a damaged propeller shaft, posing risks to both the vessel's performance and the safety of maritime operations. Key challenges included:

- Propeller Shaft Damage: The propeller shaft had suffered mechanical damage, affecting the vessel's propulsion system and necessitating immediate attention.

- Operational Downtime: The damaged propeller shaft resulted in operational downtime, impacting the shipping company's schedules and leading to financial losses.

- Precision Extraction: The extraction of the damaged propeller shaft required precision fastening techniques to ensure safe removal without causing additional damage to the vessel's structure.

Dependable Marine Engineering Services LTD Approach

Our team devised a comprehensive strategy to address the challenges associated with the fastening and removal of the damaged propeller shaft:

- Damage Assessment: Our technicians conducted a detailed assessment of the propeller shaft, identifying the specific areas of damage and the extent of the mechanical issues.

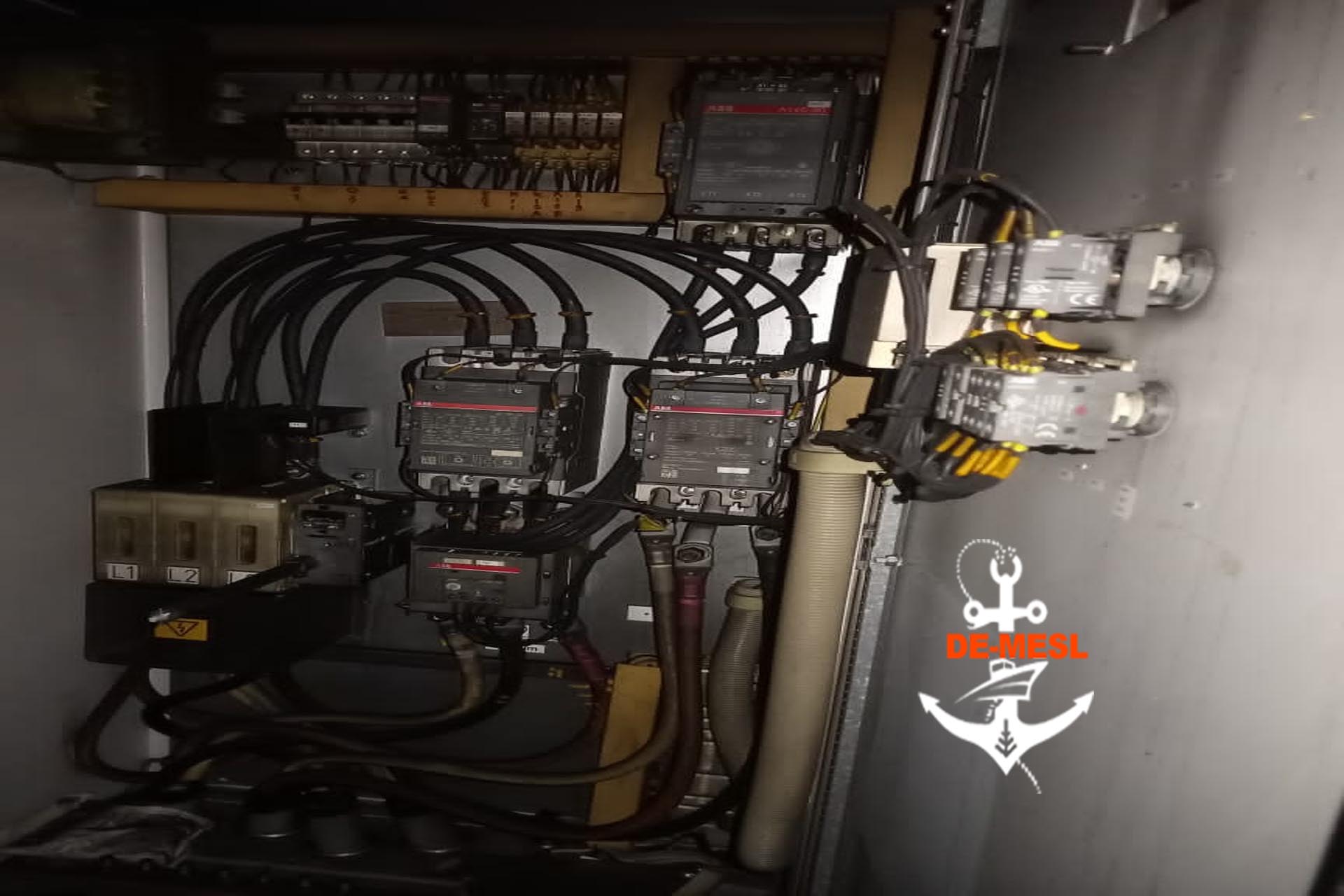

- Fastening Techniques: Based on the assessment, we developed and implemented specialized fastening techniques to secure the damaged propeller shaft, preventing further movement or damage during the extraction process.

- Customized Extraction Plan: A customized extraction plan was formulated, outlining the step-by-step process for safely removing the fastened propeller shaft while minimizing stress on the vessel's structure.

- Hydraulic Systems: We employed advanced hydraulic systems and equipment to facilitate the controlled and gradual extraction of the propeller shaft, ensuring precision and minimizing the risk of additional damage.

- Quality Assurance: Rigorous quality checks were performed throughout the extraction process to verify the success of the fastening techniques and the overall structural integrity of the vessel.

Outcome

Dependable Marine Engineering Services LTD successfully completed the fastening and extraction of the damaged propeller shaft. Key outcomes included:

- Minimized Downtime: The precision fastening and extraction techniques minimized operational downtime, allowing the vessel to resume its maritime activities promptly.

- Preserved Structural Integrity: The customized extraction plan and fastening techniques ensured the preservation of the vessel's structural integrity, preventing additional damage during the removal of the damaged propeller shaft.

- Client Satisfaction: The shipping company expressed satisfaction with the efficiency and effectiveness of Dependable Marine Engineering Services LTD's approach, highlighting our commitment to excellence in maritime engineering.

Conclusion

This case study illustrates Dependable Marine Engineering Services LTD's expertise in addressing complex challenges associated with the fastening and extraction of damaged propeller shafts. Our commitment to precision, customized solutions, and client satisfaction ensures the optimal performance and safety of maritime assets.

Gallery